Global caster solutions for OEMs, distributors & business partners in every industry

Wheelsway is your trusted caster partner — providing diverse, customized, and cost-effective solutions through collaboration with leading manufacturers

As your independent partner, we transform sourcing complexity into certainty: trusted manufacturers, on-site quality oversight by our team, controlled lead times, and optimized costs on every project.

To be the first choice for businesses worldwide seeking caster solutions — a trusted partner recognized not only for product quality, but for helping clients move faster, safer, and smarter toward long-term success.

We believe casters are more than parts — they are the small innovations that keep entire industries rolling. Our passion lies in turning everyday mobility challenges into opportunities for efficiency, reliability, and growth for our clients.

We had rich factory based experience working with distributors, MROs, OEMs, etc, which gave us deep insight into what customers value most and where traditional suppliers often fall short.

Practical knowledge of compliance standards such as EN12530, EN1004, OSHA, ASTM, RoHS, and REACH.

Proven understanding of common customer challenges: quality drift, long lead times, and high ownership costs.

Enjoy free caster samples in just 2–3 days and production lead-time within 20 days.

We welcome small orders to start our partnership, offering personalized service and collaboration from day one.

We address and resolve issues promptly to keep your operations running smoothly.

We follow a detailed step-by-step process to ensure that your project runs smoothly and without any problems.

Define requirements: Understand the customer’s specific needs and requirements. Consider special attachments, test standards, and industry standards. Give suggestions to improve the caster performance if the customer wants to eliminate the failure issues from their existing casters.

Material selection: Select appropriate wheel materials for the casters based on factors like load capacity, environmental conditions, and durability requirements.

Technical Drawings: Make detailed 2D/3D technical drawings of the caster based on the customer’s requirements or samples.

Prototyping: Develop prototypes to test the functionality and performance of the casters. It can be a 3D printing model or a small batch for initial testing.

Tooling and Equipment Setup: On the basis of the finalized design, set up and adjust the necessary tooling and equipment for mass production.

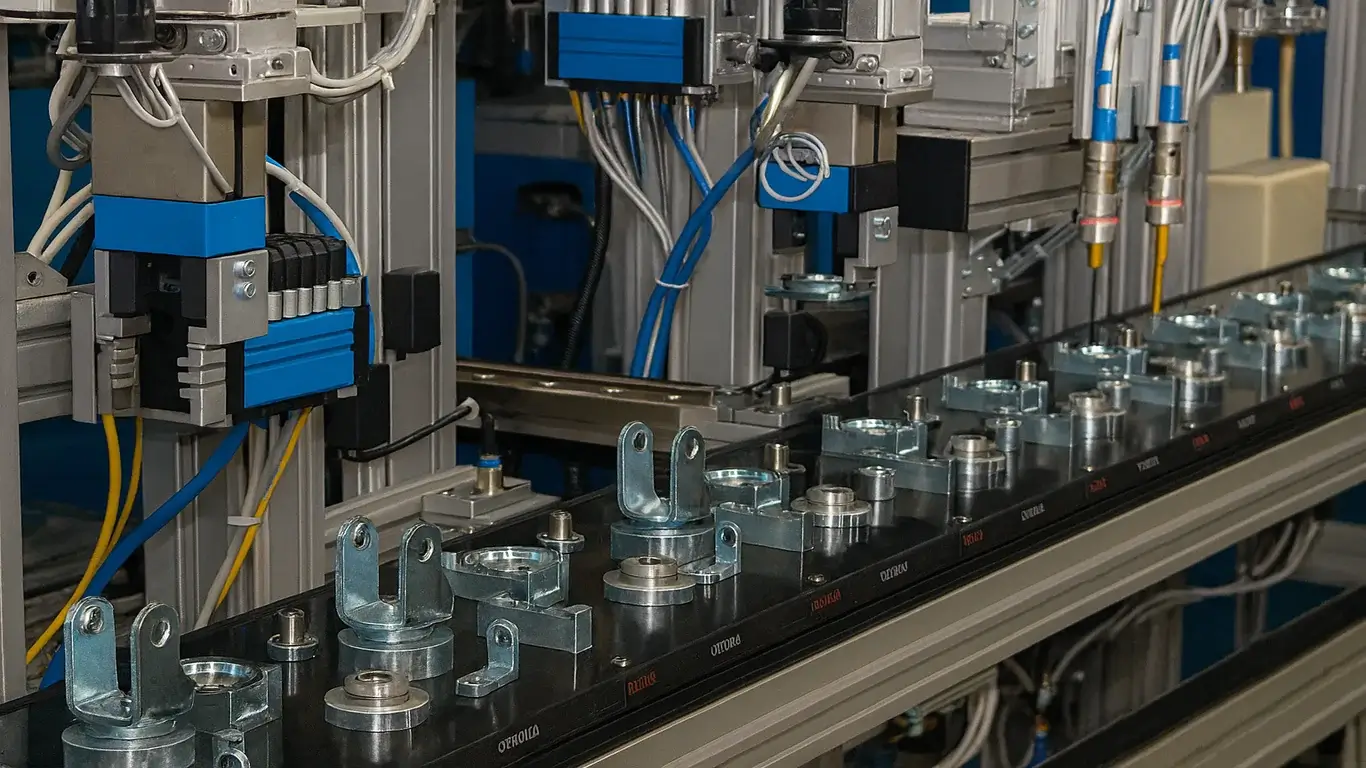

Production of Components: Manufacture individual caster components such as wheels and frames, according to technical specifications in confirmed drawings.

Surface Treatment: Apply surface treatments to enhance the aesthetics, corrosion resistance, hardness, or other functional aspects of the casters.

Assembly: Assemble the casters, making sure that each unit meets the design specifications and quality standards.

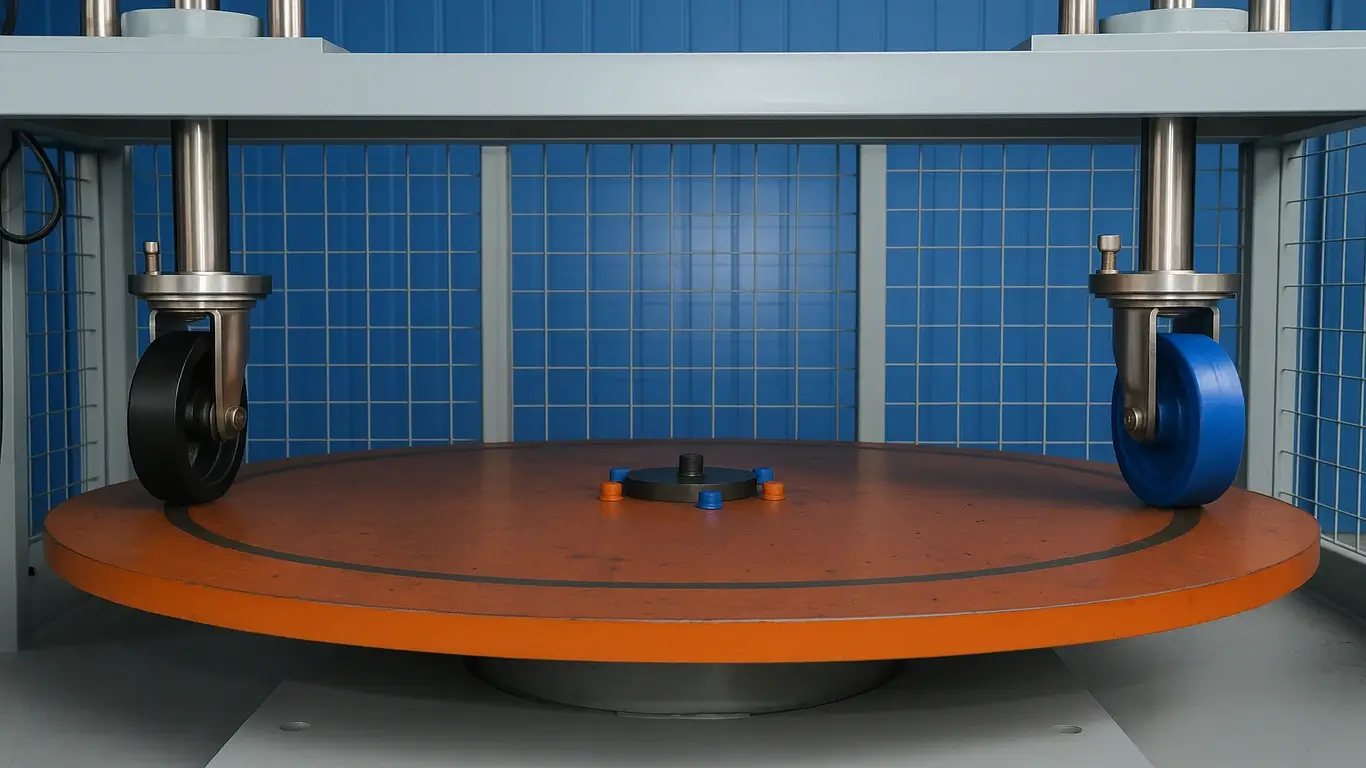

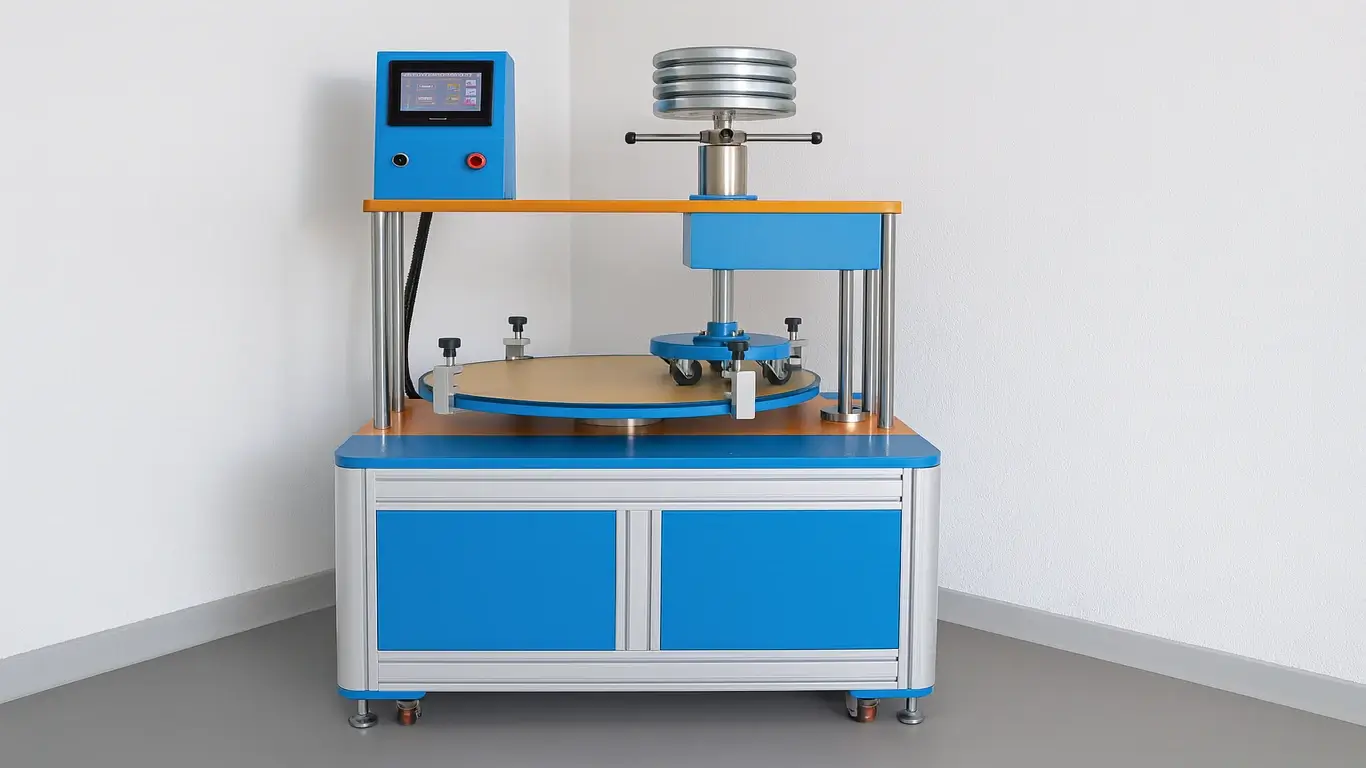

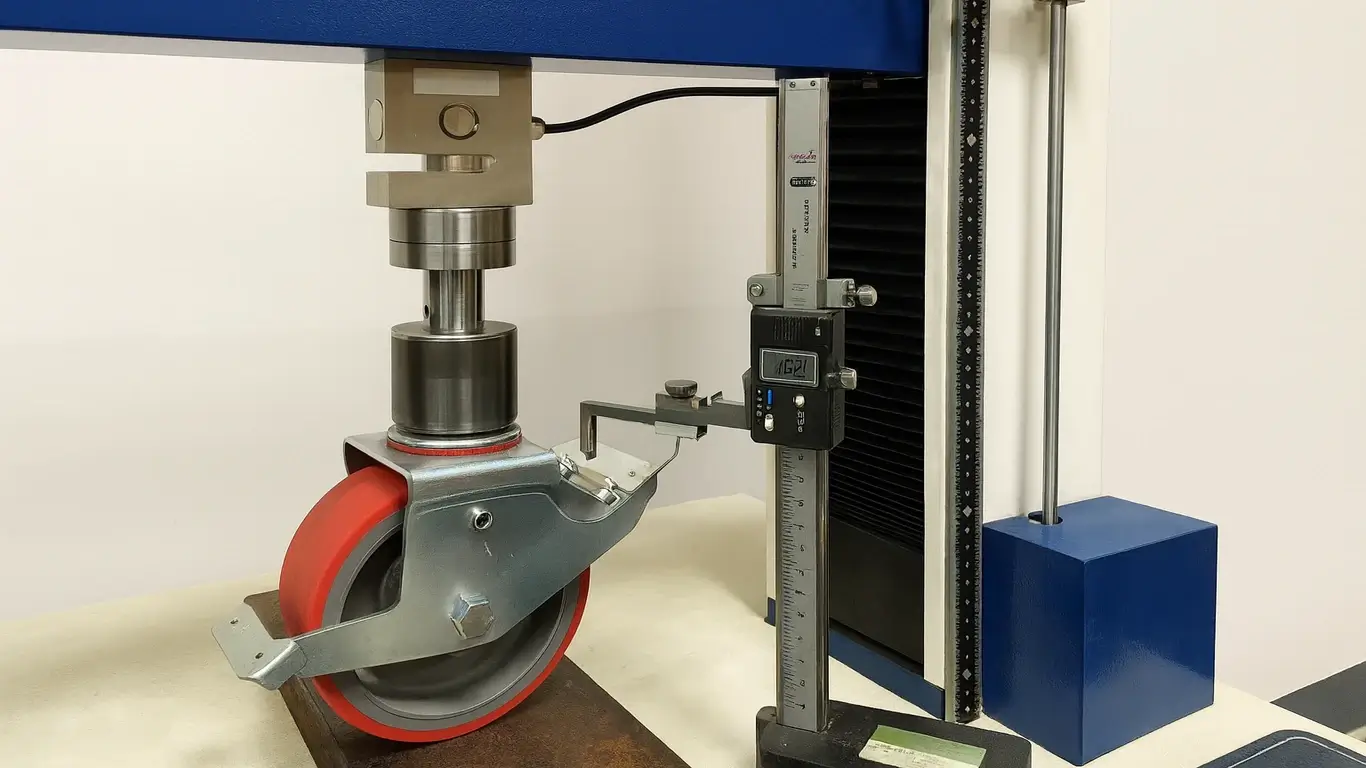

Load Testing: Test the casters according to the dynamic load test standard, such as EN12532, or conform to the test requirements of the customer. To ensure that the casters can handle the specified weight capacities without failure.

Durability Testing: Test the casters for durability under various conditions, such as different floor surfaces and temperature extremes, according to the customer’s demand.

Quality Control Checks: Implement ISO9001 quality control measures throughout the manufacturing process. Identify and correct any defects.

Packaging: Develop packaging solutions that protect the casters during transportation and storage.

Shipping Logistics: Plan and coordinate the logistics for shipping the casters to the client, and confirm the paperwork details with the customer, such as invoice and packing list, bill of lading, Certificate of Original, Form E, etc.

Customer Support: Provide ongoing support to address any queries, concerns, or further needs that the client may have after receiving the casters.

All caster components are standardized and produced by automated blanking, forming, and assembly.

All casters are tested on specialized machines in compliance with relevant industry standards.

Tell us your caster needs today—we’ll respond with a tailored solution within 24 hours.

*We respect your privacy and all your information are protected.