Wheelsway delivers high-performance industrial casters and material handling wheels for demanding environments such as factories, warehouses, and logistics centers. Designed for carts, racks, and a wide range of material handling equipment, our medium-duty and heavy-duty casters provide reliable, long-lasting mobility.

Each product combines proven manufacturing quality with expert sourcing to ensure smooth, efficient, and safe material movement. Partner with us, let’s find a solution with strength and precision, specially for you.

Casters and wheels for industrial and material handling are mobility solutions designed to move goods, equipment, and containers efficiently in warehouses, factories, distribution centers, airports, and transport hubs. They are mounted on trolleys, racks, carts, AGVs (automated guided vehicles), conveyor systems, and even heavy-duty containers to ensure smooth, reliable, and safe movement of loads.

We provide solutions to the demands of modern supply chains. Explore the key features below and see how our products can power your equipment and streamline your workflow and discover our complete range of industrial and material handling casters and wheels—designed to keep your equipment moving with efficiency and reliability.

Stand up to heavy use and tough industrial conditions with reliable performance over time.

For wide range of equipment and environments, offering smooth mobility for everything from light carts to heavy industrial systems.

Precision bearings and quality materials ensure effortless movement, reducing friction and improving handling across all surfaces.

Optimized design and reliable performance help streamline material flow, saving time and effort in daily operations.

Casters and wheels for pallet trucks, stackers, dollies,warehouse carts, pick up carts, trolleys, stack racks, heavy duty mobile storage units, etc

24~72 hours salt spray test passed

500 hours salt spray test passed

1,000 hours salt spray test passed

75mm~125mm

Bearing options: Double ball bearings

Bearing option: Double ball bearings

Bearing options: Single ball bearing

Bearing options: Double ball bearings

Up to 150KGs

24~72 hours salt spray test passed

500 hours salt spray test passed

1,000 hours salt spray test passed

80mm~200mm

Bearing options: Plain bushing / Roller bearing / Single ball bearing (can withstand -30℃)

Bearing: Plain bushing

Bearing: Roller bearing

Bearing options: Roller bearing / Ball bearing

Bearing: Double ball bearings

Bearing options: Single ball bearing

Up to 300KGs

24~72 hours salt spray test passed

240 hours salt spray test passed

500 hours salt spray test passed

1,000 hours salt spray test passed

100mm~200mm

Bearing options: Roller bearing / Double ball bearings

Bearing options: Roller bearing / Double ball bearings

Bearing options: Roller bearing / Double ball bearings

Bearing: Double ball bearings

Bearing: Double ball bearings

Up to 350KGs

24~72 hours salt spray test passed

100mm~360mm

Bearing: Double ball bearings

Up to 8,000KGs

AGV, AMR, AS/RS,RGV, OHT, OHS, stocker, etc

80mm~350mm

Customizable

24~72 hours salt spray test passed

500 hours salt spray test passed

40mm~150mm

Bearing: Double ball bearings

Bearing options: Roller bearing / Double ball bearings

Up to 1,400KGs

80mm~400mm

Customizable

35mm~90mm

Customizable

Casters and wheels for shipping container handling, heavy-duty logistics dollies, etc

240 hours salt spray test passed

150mm~400mm

Bearing options: Roller bearing / Double ball bearings

Bearing options: Roller bearing / Double ball bearings

Up to 2,000KGs

EN 12527 is the foundational European standard that defines how to test the performance of caster wheels and castors. It specifies in detail the test methods and apparatus used to evaluate factors like strength, durability, and safety. (standards.iteh.ai). This standard itself does not set the pass/fail values for every caster type; instead, it provides general procedures. Specific acceptance criteria for different caster categories (furniture, medical, industrial, etc.) are given in the respective specialized standards

EN 12530 specifies the technical requirements, dimensions, and testing criteria for castors and wheels used in manually propelled institutional applications. This standard covers medium-duty equipment castors found in public and institutional facilities such as shops, restaurants, hotels, schools, and hospitals. Castors under EN 12530 may include features like wheel brakes or swivel locks, as these are common in carts and equipment used in such environments. The standard ensures that these casters meet appropriate safety and performance levels for frequent manual handling in public spaces

EN 12531 is a dedicated standard for hospital bed casters, reflecting the specialized requirements of medical beds. It specifies the technical requirements, standard dimensions, and testing conditions for swivel castors used on hospital beds. This standard applies to hospital bed castors that are typically larger in diameter (100 mm or above) and equipped with a central locking mechanism. In practice, central locking allows a set of casters to be locked or unlocked simultaneously for patient safety and ease of movement. The scope of EN 12531 primarily covers swivel casters in this medical context, ensuring they meet strict safety and performance needs.

EN 12532 addresses transport castors and wheels intended for industrial applications where equipment is moved at speeds up to 1.1 m/s (4 km/h). This is roughly a fast walking speed, indicating the standard is for carts or trolleys that might be pushed or towed slowly in warehouses or factories. The standard lays out technical requirements, dimensions, and testing for casters used on non-powered or hand-towed industrial transport equipment. EN 12532 explicitly excludes certain categories: it does not apply to furniture or office chair casters, institutional or hospital bed casters, or any powered/driven equipment casters. Those excluded categories are covered by other standards (e.g., furniture by EN 12528/12529, hospital by EN 12531, and higher-speed driven equipment by EN 12533). Essentially, EN 12532 is focused on wheels and castors for manually propelled or tugged industrial carts and platform trucks operating at low speeds.

EN 12533 is the standard for heavy-duty castors and wheels used in applications where travel speeds are higher than walking pace – specifically over 1.1 m/s (4 km/h) and up to 4.4 m/s (16 km/h). It covers castors (including any accessories like brakes) designed for mechanical or power-driven applications in this speed range. This means equipment that is either powered or towed by a vehicle, moving at moderate running speeds. EN 12533 represents the upper end of caster usage, where significant dynamic forces occur due to higher speeds. The standard sets out technical specs, dimensions, and required tests to ensure safety and performance at these speeds. Importantly, EN 12533 excludes certain wheel types: pneumatic-tyred wheels (inflatable wheels) and dedicated drive wheels are not covered, as those may fall under other vehicle or machinery standards.

Designing and manufacturing custom casters for an OEM project involves several stages, we follow a detailed step-by-step process to ensure that your project runs smoothly and without any problems

Define requirements: Understand the customer’s specific needs and requirements. Consider special attachments, test standards, and industry standards. Give suggestions to improve the caster performance if the customer wants to eliminate the failure issues from their existing casters.

Material selection: Select appropriate wheel materials for the casters based on factors like load capacity, environmental conditions, and durability requirements.

Technical Drawings: Make detailed 2D/3D technical drawings of the caster based on the customer’s requirements or samples.

Prototyping: Develop prototypes to test the functionality and performance of the casters. It can be a 3D printing model or a small batch for initial testing.

Tooling and Equipment Setup: On the basis of the finalized design, set up and adjust the necessary tooling and equipment for mass production.

Production of Components: Manufacture individual caster components such as wheels and frames, according to technical specifications in confirmed drawings.

Surface Treatment: Apply surface treatments to enhance the aesthetics, corrosion resistance, hardness, or other functional aspects of the casters.

Assembly: Assemble the casters, making sure that each unit meets the design specifications and quality standards.

Load Testing: Test the casters according to the dynamic load test standard, such as EN12532, or conform to the test requirements of the customer. To ensure that the casters can handle the specified weight capacities without failure.

Durability Testing: Test the casters for durability under various conditions, such as different floor surfaces and temperature extremes, according to the customer’s demand.

Quality Control Checks: Implement ISO9001 quality control measures throughout the manufacturing process. Identify and correct any defects.

Packaging: Develop packaging solutions that protect the casters during transportation and storage.

Shipping Logistics: Plan and coordinate the logistics for shipping the casters to the client, and confirm the paperwork details with the customer, such as invoice and packing list, bill of lading, Certificate of Original, Form E, etc.

Customer Support: Provide ongoing support to address any queries, concerns, or further needs that the client may have after receiving the casters.

When selecting caster wheels for material handling in logistics operations, consider factors like load capacity, floor conditions, and movement requirements. For heavier loads or high-frequency use, heavy-duty industrial casters for logistics equipment provide better durability and safety. Also evaluate the environment – for example, temperature extremes or outdoor use might require specialized wheel materials (such as high-temperature nylon or corrosion-resistant coatings). By matching the caster type (swivel, rigid, brake) and wheel material (polyurethane, rubber, steel, etc.) to your specific application, you ensure smooth and safe mobility. Our range covers everything from medium-duty caster wheels for material handling carts to extra-tough models for automated systems, making it easy to choose the perfect caster for your needs. For more informations, you can also check our How to choose the Best Heavy-Duty casters.

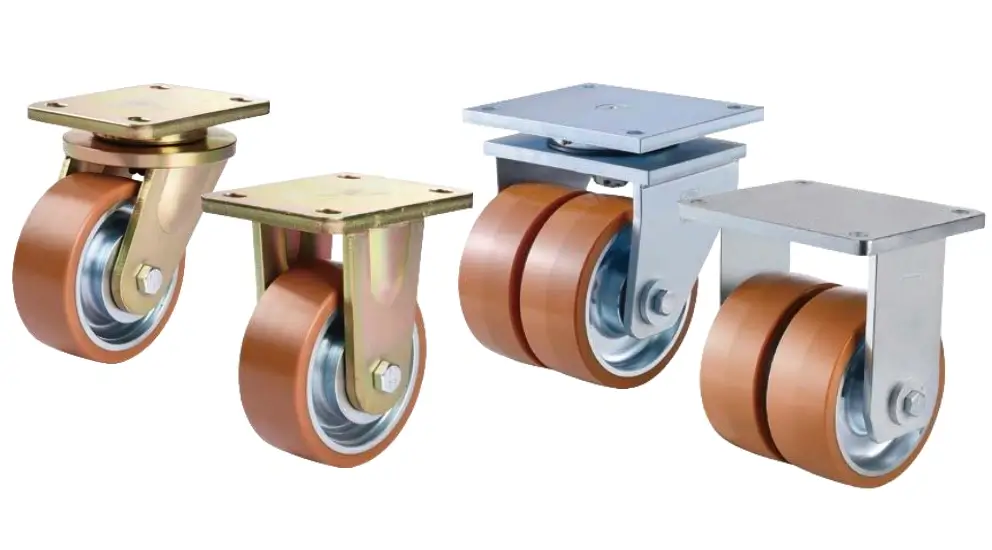

Medium-duty casters are designed for moderate loads (typically a few hundred kilograms per wheel) and are ideal for standard carts, racks, and equipment. Heavy-duty casters are built for very high load capacities – often supporting thousands of kilograms – using reinforced steel frames, larger wheel diameters, and special bearings. These robust casters handle the stress of heavy machinery and continuous operation; for example, heavy-duty wheels for automation systems or large industrial carts offer greater stability and wear resistance. In contrast, medium-duty casters are a cost-effective choice for everyday material handling where extreme capacity isn’t required. Ultimately, use medium-duty casters for lighter equipment and upgrade to heavy-duty casters when you need maximum strength, durability, and 24/7 performance.

“European type” industrial casters refer to caster designs built to European standards and style, emphasizing robust construction and safety features. They often use high-quality pressed steel brackets (with zinc plating for corrosion resistance) and can include twin-wheel configurations or integrated wheel locks common in European designs. Many global OEM manufacturers and logistics operations prefer European type casters because they are interchangeable with European-made equipment and meet strict EN/ISO standards for industrial use. In practice, choosing European style casters ensures compatibility with international equipment and confidence in quality – these casters are known for smooth performance, durability, and reliable brakes that comply with EU safety regulations. Adopting European type casters can be especially beneficial if your material handling systems need to align with global or European norms.

For moving shipping containers or very heavy cargo, specialized shipping container casters are recommended. These are ultra heavy-duty casters engineered to handle massive weights (often several tons per caster) and designed to interface with standard container fittings. Shipping container caster sets typically feature a built-in twist-lock or pin that secures into a container’s ISO corner block, ensuring safe attachment. They use large diameter wheels – often steel or high-capacity polyurethane – to roll smoothly under extreme loads without failing. By equipping a container with these high-capacity casters, a single container or oversized load can be maneuvered around a warehouse or yard without cranes. Always ensure the caster’s load rating comfortably exceeds the total weight of your container and contents for safe, efficient handling of heavy cargo.

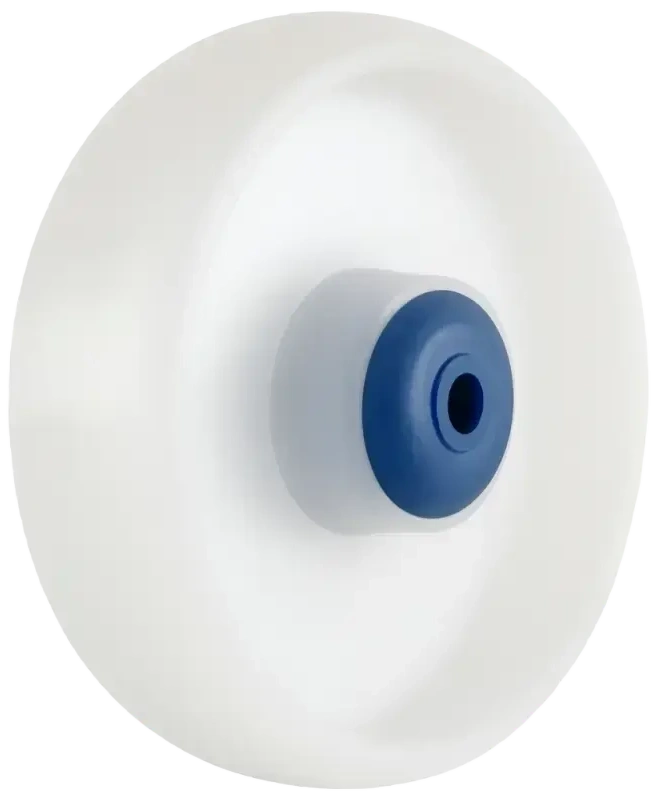

AGV drive wheels are the powered wheels that provide propulsion and steering for Automated Guided Vehicles (AGVs) and other autonomous mobile robots. Unlike free-swiveling caster wheels, drive wheels are connected to the vehicle’s motors or gearboxes, delivering the traction and precise movement control needed for automation. They are typically made of durable materials (for example, a high-strength polyurethane tread bonded to an aluminum or steel core) to ensure they can run 24/7 and still protect the floor surface. High-quality AGV drive wheels are crucial for maintaining accurate navigation, load carrying capacity, and safety in automated operations. Choosing the right drive wheels ensures your AGVs and AMRs can move heavy loads efficiently, stop reliably, and operate with minimal maintenance downtime in a busy industrial environment.

Yes. We offer a range of specialized casters and wheels designed for automated material handling systems. This includes dedicated AGV casters and heavy-duty wheels for automation systems such as AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots), which require high load capacity and continuous duty performance. We also supply drive wheels and components for other automation equipment – for example, RGVs (Rail-Guided Vehicles), conveyor shuttles, and overhead transport systems (OHT/OHS) used in factories or warehouses. Our products even cover the needs of automated storage and retrieval systems like stacker cranes and stocker units, as well as high-speed sorting system wheels for automated sortation lines. All these wheels and casters are engineered for durability, precision tracking, and low noise, ensuring they can keep advanced logistics systems running smoothly with minimal downtime.

Absolutely. We provide extensive customization options to meet specific project requirements or OEM applications. Our engineering team can tailor caster and wheel solutions in terms of size, load capacity, wheel material, and mounting style to fit your equipment. For example, you can request specialized wheel materials – from anti-static or ESD-safe treads for sensitive electronics factories to high-temperature-resistant wheels for ovens, or extra-soft treads for quiet operation. We also offer custom mounting plates, bolt patterns, brake configurations, and even color or branding customization for large OEM orders. Whether you need a unique drive wheel for a new AGV design or a specific caster size for a modified cart, we can develop a solution that integrates seamlessly. This level of customization ensures you get optimal performance and the perfect fit for your application.

Our industrial casters and wheels are manufactured under strict quality control and meet international standards for safety and performance. We adhere to ISO 9001 quality management in production to ensure consistency and reliability in every batch. Many of our caster wheels are also compliant with RoHS and REACH regulations, indicating they are made from materials safe for use in global markets (free of hazardous substances). For customers in regulated industries or regions, we can provide products with relevant certifications or markings – for example, casters that meet European EN standards and carry the CE mark where applicable. Additionally, our heavy-duty models undergo rigorous testing (such as dynamic load and durability tests) to verify they can handle stated capacities over prolonged use. These certifications and tests give procurement managers confidence that our casters and wheels will perform safely and last long in demanding industrial environments.

Advanced caster and wheel designs can significantly boost operational efficiency and workplace safety. For example, precision ball bearings and maintenance-free swivels minimize rolling friction, meaning carts or AGVs require less force or power to move – this reduces strain on workers and extends battery life for automated vehicles. Shock-absorbing casters are another innovation; they cushion impacts and vibrations, protecting fragile cargo and equipment when moving over uneven floors or thresholds. Likewise, modern wheel materials like high-traction, non-marking polyurethane improve safety by providing better grip and protecting floors (no scuffs or debris, which lowers slip hazards). Some heavy-duty casters also feature directional locks or ergonomic foot brakes that improve control and worker safety when parking loads. Overall, these innovations in caster wheels for material handling lead to smoother workflows, fewer accidents, and lower maintenance costs in logistics operations.

Yes, we support customers worldwide. We offer global shipping for all our caster and wheel products, ensuring fast delivery and logistics support to your location. Each purchase comes with a warranty against manufacturing defects, and our after-sales support team is available to assist with installation, technical questions, or any issues that arise. As a supplier to international logistics companies and OEM manufacturers, we understand the importance of reliable fulfillment – we maintain inventory and work with trusted freight partners to deliver on time across different regions. Our goal is to make sure procurement managers and engineers anywhere in the world can source our high-quality casters and wheels with confidence and get prompt support whenever needed.

*We respect your privacy and all your information are protected.