There are several types of bearings commonly used in caster wheels, including plain bearings, needle roller bearings, tapered roller bearings, thrust ball bearings, ball bearings, and delrin bearings.

Bearings are mechanical components that reduce friction between moving parts, allowing wheels to rotate smoothly. In caster wheels, they’re the key that makes movement effortless.

If you’re curious about how these different bearings impact the performance of your caster wheels and which type might be the best fit for your needs, keep reading. I’ve got plenty of insights to share that will help you make an informed decision.

Understanding Bearings in Caster Wheels

Think of bearings as the unsung champions of smooth movement, they’re small components tucked inside your caster wheels that play a huge role in how easily things roll.

The Role of Bearings

- Reducing Friction: Bearings minimize resistance, making it easier to roll heavy loads.

- Supporting Loads: They distribute weight evenly, enhancing the wheel’s durability.

- Improving Maneuverability: Quality bearings make it simpler to change direction and navigate tight spaces.

Without good bearings, even the best wheels can feel like they’re dragging through mud.

Types of Bearings in Caster Wheels

Now, let’s get into the nitty-gritty—the different types of bearings you’ll find in caster wheels. Each type has its own set of pros and cons, and choosing the right one depends on your specific needs.

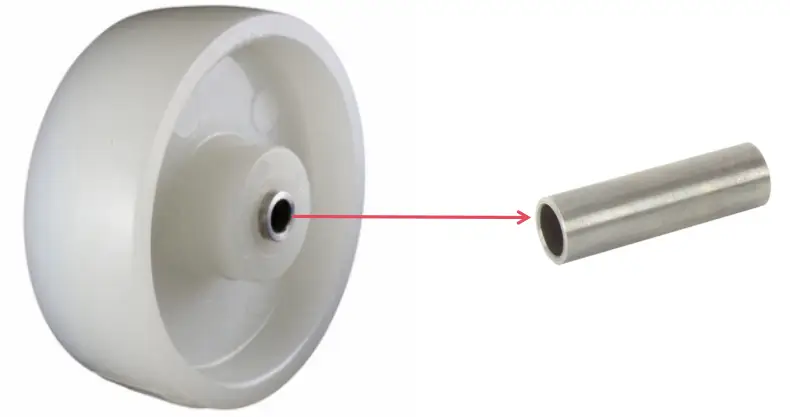

1. Plain Bearings (Sleeve Bearings)

What is a Plain Bearing? Plain Bearings/ Sleeve Bearings consist of a metal sleeve inserted into a wheel, allowing it to rest directly on the axle. These bearings are ideal for applications where smooth rolling is less critical, offering a simple and cost-effective solution for low-speed or low-precision uses.

- Pros:

- Cost-effective

- Low maintenance

- Cons:

- Higher friction compared to other types

- Roller bearings can be noisy

- Not ideal for heavy loads or high-speed applications

2. Needle Roller Bearings

What is a Roller Bearing? A roller bearing use long, thin cylindrical rollers resembling needles and features (or without) a split outer race shell that houses the roller assembly for enhanced load capacity. Besides the standard design, roller bearings are also available in stainless steel.

- Pros:

- Robust and Durable

- Low Maintenance

- Low Rolling Resistance

- Cons:

- Not as smooth for high-speed applications

- Can be more expensive than plain bearings

- Potential for Debris Accumulation

You can learn more about this concept by watching this video.

3. Tapered Roller Bearings

What is a Tapered roller bearing? Tapered roller bearings are rolling element bearings capable of supporting both axial and radial forces. This makes them ideal for handling combined loads, functioning effectively as both thrust and radial bearings.

- Pros:

- Great for combined load applications

- Ideal for precise alignment needs

- Cons:

- More complex design

- Higher cost and may require more maintenance

If you’d like a more in-depth explanation, take a look at this article.

4. Thrust Ball Bearings

What is a Thrust Ball Bearing? A thrust ball bearing is a specialized rotary bearing designed to support axial loads. Unlike other bearings that handle radial loads, thrust bearings primarily manage forces parallel to the axis of rotation, ensuring smooth operation under axial pressure.

- Pros:

- Low friction

- more durable

- can support axial loads in one or two directions

- Cons

- cannot transmit radial loads

- are prone to misalignment

- struggle under very large loads

You can learn more about the thrust ball bearing by reading this article with comprehensive explanation.

5. Ball Bearings

What is a Ball Bearing? A ball bearing is a precision component with hardened balls rolling between inner and outer rings, reducing friction and supporting loads. Used in heavy-duty equipment, it’s sealed against dust and pre-lubricated for maintenance-free operation. Variants include Z-bearings(metal shielded) and RS bearings(rubber sealed), with stainless steel options for specific applications.

Ball bearings reduce friction between moving parts by using two rings, or ‘races.’ The rotating balls minimize surface contact, lowering friction compared to flat surfaces rubbing together.

- Pros:

- Maintenance-free

- Long-lasting performance

- Low noise

- Low friction

- Cons:

- Higher initial cost than roller bearings

- can deform under excessive loads

If you’d like a more in-depth explanation, take a look at this article about ball bearing.

6. Delrin Bearings

What is a Delrin Bearing? A Delrin bearing is a durable, corrosion-resistant plastic bearing made by DuPont. It resists cracking under normal operating conditions when used within its specified performance limits.

- Pros:

- Corrosion-resistant

- Lightweight and quiet operation

- Cons:

- Not suitable for extreme loads

- Limited temperature tolerance

Choosing the Right Bearing for Your Caster Wheels

Selecting the right bearing isn’t rocket science, but there are some key factors to consider.

1. Load Capacity

The weight your caster wheels need to support is a critical factor in choosing the appropriate bearing.

Heavy loads

If you’re moving heavy equipment or machinery—like industrial carts, warehouse pallets, or heavy-duty medical equipment—you’ll need bearings that can handle substantial weight without compromising on performance.

- Ball Bearings: Known for their smooth operation and low friction, ball bearings are perfect for applications where speed and maneuverability are essential.

- Tapered Roller Bearings: Designed to manage both radial and axial loads, these bearings are ideal when you require precise alignment under heavy weight. Their conical rollers can support significant loads while maintaining smooth operation.

Light to Medium Loads

For applications involving lighter loads, such as office chairs, shopping carts, or lightweight trolleys, bearings that offer ease of movement and cost-effectiveness are suitable.

- Roller Bearings: These bearings use cylindrical rollers, providing a larger contact area to distribute weight evenly. They’re excellent for handling heavy loads and are durable under high stress.

- Plain Bearings (Sleeve Bearings): These are simple and cost-effective, suitable for light loads where high-speed movement isn’t a priority. They’re low maintenance and get the job done for basic applications.

2. Environment

Wet or Corrosive Conditions

In environments exposed to moisture, chemicals, or extreme temperatures—such as food processing facilities, laboratories, or outdoor settings—you need bearings that can withstand these harsh conditions.

- Delrin Bearings: Made from a type of plastic known as Delrin, these bearings are corrosion-resistant and ideal for wet or chemically aggressive environments. They’re also lightweight and require minimal maintenance.

- Precision Sealed Bearings: These bearings are enclosed with seals to protect against contaminants like dust, water, and chemicals. They offer long-lasting performance with low maintenance, making them perfect for challenging environments.

Clean, Indoor Use

For controlled indoor environments like offices, hospitals, or retail stores, standard bearings are often sufficient.

- Standard Ball Bearings: Provide smooth, quiet operation, which is ideal in settings where noise reduction is important.

- Roller Bearings: If you’re handling heavier loads indoors, roller bearings offer durability and efficiency without the need for specialized corrosion resistance.

3. Speed and Maneuverability

- High-Speed Needs: Need to move quickly? Ball bearings offer smoother rotation for speedier movement.

- Precision Movement: For tasks requiring careful navigation, tapered roller bearings provide better control.

4. Additional Factors to Consider

Maintenance Requirements

- Low Maintenance Options: If you prefer bearings that require minimal upkeep, consider precision sealed bearings or Delrin bearings. Their sealed designs protect against contaminants, reducing the need for frequent cleaning and lubrication.

- Regular Maintenance Needs: Bearings like plain bearings may require regular lubrication and cleaning to maintain optimal performance.

Cost Considerations

- Budget-Friendly Choices: Plain bearings and standard ball bearings are generally more affordable and suitable for applications where cost is a significant factor.

- Long-Term Investment: While bearings like tapered roller bearings or precision sealed bearings may have a higher initial cost, their durability and low maintenance needs can offer better value over time.

Noise Levels

- Quiet Operation: In environments where noise reduction is important—such as hospitals, libraries, or offices—opt for ball bearings with proper lubrication to ensure silent operation.

Compatibility and Installation

- Ensure Fit: Always verify that the bearing you choose is compatible with your caster wheel’s dimensions and specifications. Mismatched components can lead to performance issues or equipment failure.

- Ease of Installation: Some bearings are easier to install and replace than others. Consider this if you anticipate the need for frequent maintenance or swapping out of parts.

Maintenance Tips for Caster Wheel Bearings

Even the best bearings need a little love to keep them performing their best. Here’s how you can extend their lifespan:

- Regular Cleaning: Dust and debris can gunk up your bearings. Give them a good wipe-down periodically.

- Proper Lubrication: A little grease goes a long way in reducing friction and preventing wear.

- Routine Inspection: Check for signs of damage like cracks or unusual noises.

Helpful Resource: For a deep dive into bearing maintenance, check out this bearing maintenance guide .

The Impact of Bearing Quality on Performance

You might be tempted to cut corners on bearing quality to save a few bucks, but trust me, it’s not worth it.

- Durability: High-quality bearings last longer, saving you money over time.

- Efficiency: Smooth operation reduces effort and increases productivity.

- Safety: Reliable bearings prevent accidents caused by wheel failure.

Common Signs of Bearing Problems

Not sure if your bearings are on their last legs? Here are some red flags to watch out for:

- Strange Noises: Grinding, squeaking, or clicking sounds when the wheel moves.

- Difficulty Moving: If pushing or pulling feels harder than it used to.

- Visible Damage: Cracks, rust, or deformities on the bearings or wheels.

So, when should you swap out those old bearings?

- Persistent Problems: If cleaning and lubricating don’t fix the issue.

- Excessive Wear: Visible signs of damage or significant wear and tear.

- Performance Drop: If your caster wheels aren’t rolling smoothly anymore.

Replacing bearings might seem daunting, but it’s a straightforward process that can save you headaches down the road.

To wrap up

Bearings might be small, but they play a huge role in how smoothly your caster wheels perform. By understanding the different types and what they’re best suited for, you’re well on your way to choosing the right bearings for your needs.

Remember, the right bearing can make all the difference between a smooth glide and a frustrating struggle. So take the time to consider your options, if you have any questions, don’t hesitate to contact or email us at eric@wheelswaycaster.com.