If you are new to casters or work with casters regularly, understanding key caster terminology is essential for making informed decisions. Whether it’s for industrial applications or enhancing furniture mobility, knowing these terms will ensure you select the perfect caster for your needs. In this guide, we’ll break down the most important technical terms related to casters to help you grasp their core components and functions.

Why Understanding Caster Terminology Matters?

Understanding caster terminology is crucial for making informed decisions about selecting and maintaining caster wheels for various applications. With the global caster wheels market valued at over $9 billion in 2022 and expected to grow at a 5.6% annual rate, it’s clear that businesses and individuals alike are increasingly relying on caster wheels for their efficiency and versatility.

For example, choosing the correct caster can improve operational efficiency by up to 30%, reduce downtime, and extend equipment lifespan. Properly understanding terms like “load capacity,” “wheel material,” and “mounting type” ensures that you invest in the most effective and reliable solutions. Whether you’re in an industrial, commercial, or residential setting, a solid understanding of caster terminology helps you avoid costly mistakes, optimize your operations, and make well-informed purchasing decisions.

Understanding the Terminology of Caster Wheels

Now that we’ve established why understanding caster terminology is essential, let’s dive deeper into the specific terms and definitions you need to know. This knowledge will empower you to make smarter decisions when selecting the right caster wheels for your needs. From basic components to advanced features, we’ll explore the key terminology that governs the world of caster wheels. Let’s get started with the most common terms you’ll encounter.

1. Swivel Caster

What is a Swivel Caster? A swivel caster is a type of caster that rotates 360 degrees, enabling smooth, omnidirectional movement. This type often comes with added features like:

- Total lock mechanism: Prevents both rolling and swiveling for complete immobilization.

- Side brake: Stops wheel rolling.

- Swivel lock: Fixes the direction of movement.

Swivel casters are ideal for applications requiring enhanced maneuverability, such as hospital beds and trolleys.

2. Rigid(fixed) Caster

What is a Rigid(fixed) Caster? Unlike swivel casters, rigid casters only move in a straight line, providing greater stability. These are commonly used in carts and dollies that don’t require frequent direction changes. Some rigid casters feature a wheel brake for added control.

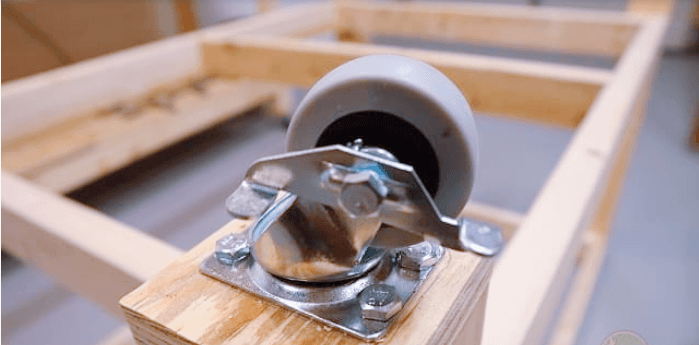

3. Mounting Plate / Top Plate

The mounting plate is the attachment point between the caster and the equipment. Typically rectangular, it features bolt holes (four or six) for secure installation. Alternative mounting systems include:

- Threaded stems

- Corner plates

- Steel pipes

Selecting the right mounting plate ensures a robust and stable connection.

4. Kingpin

The kingpin is the bolt or rivet that holds the swivel mechanism together, allowing the caster to rotate. A durable kingpin enhances swiveling smoothness and caster longevity over time.

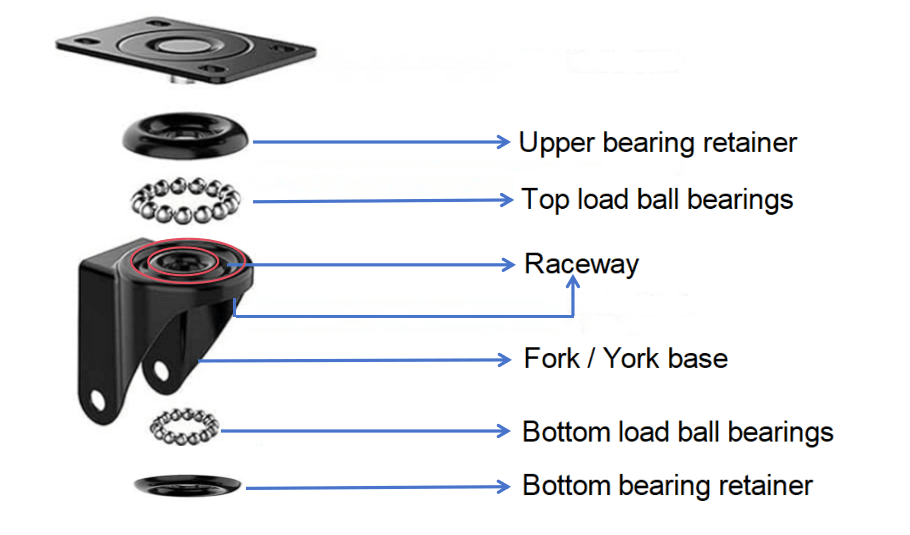

5. Load ball bearings / Swivel Bearings

On swivel casters, load ball bearings are steel balls located in the raceway between the fork base and the mounting plate or bearing retainer of a swivel caster.

They roll to counteract direct thrust and component thrust . The load ball bearings allow the wheel to rotate 360 degrees, offering directional flexibility and easier navigation.

There are two structure types of load ball bearings (swivel bearings):

Single ball race: A single row of steel balls between the fork and top plate (upper ballrace).

Double ball race: An additional row of steel balls in a larger diameter ball raceway(bottom ballrace) underneath the fork .

6. Fork / York

The fork, also known as the york, is the structural frame that holds the wheel. Forks are made of welded or pressed steel, which determines the caster’s strength and whether it swivels or remains rigid.

7. Housing / Bracket

All the above parts connected become a complete caster housing.

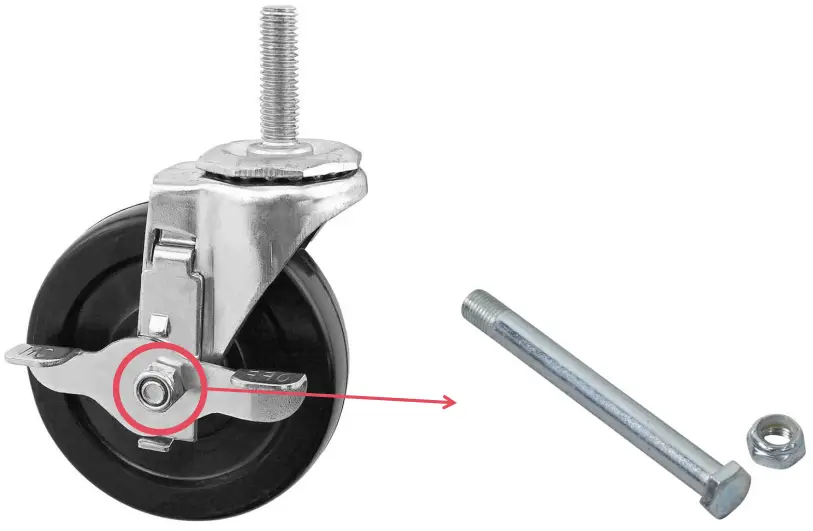

8. Axle & Nut

The axle nut secures the axle in place, keeping the wheel and other components attached to the caster. This small but crucial part ensures smooth operation and helps to keep the wheel aligned.

9. Wheels

The wheels of caster come in various materials, including:

- Polyurethane: Noise reduction and floor protection.

- Rubber: Enhanced grip.

- Nylon: Resistant to wear.

- Cast iron: Suitable for harsh environments.

Choosing the right wheel material depends on load requirements, flooring, and environmental conditions.

10. Wheel Bearings

Inside the wheel, bearings play an important role in making the wheel roll smoothly and quietly by minimizing friction and noise. There are three common types of bearing: precision caster ball bearing, roller bearing (including Nylon cage type and steel cage type), and plain bearing.

11. Tread Guard

The tread guard protects the bearings from dirt, debris, and thread buildup, which can compromise the caster’s performance. This feature is essential for maintaining longevity in high-traffic environments.

12. Caster Pad

So,what is a Caster Pad? The caster pad, also known as a quick-change or quick-release caster pad, is a metal plate that’s either welded or bolted to the underside of equipment. It features raised edges that enable quick installation or replacement of casters, without the need to remove four bolts for each mounting plate (which would otherwise mean dealing with 16 bolts for a set of four casters). This design is intended to improve efficiency for large industrial companies that frequently replace casters, allowing for easy changes without requiring complex tools.

Check out this video below for a clearer understanding of how the caster pad works.

13. Total Lock Mechanism: Double brake / Dual brake

A total lock mechanism stops both the wheel and the swivel action, providing complete immobilization of the caster for maximum stability. This is vital for safety in medical or manufacturing equipment.

14. Swivel Lock

The swivel lock is a mechanism that prevents the caster from rotating, transforming a swivel caster into a rigid one when needed for added stability.

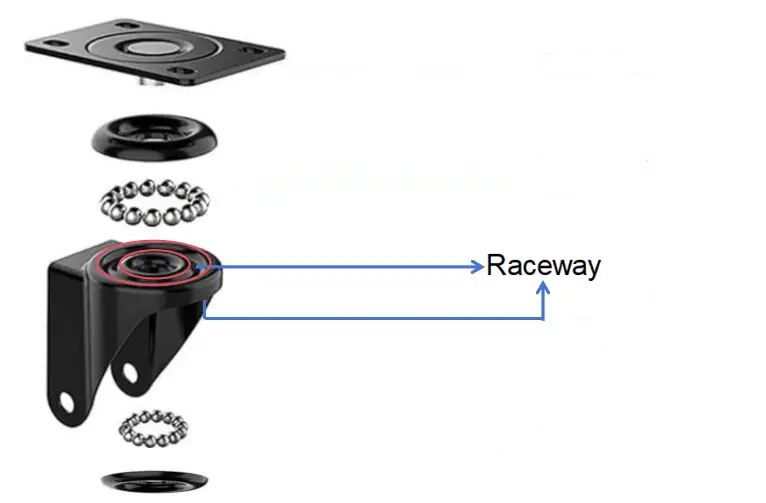

15. Raceway

The raceway is the surface within the swivel mechanism where the bearings roll. A smooth raceway ensures fluid swiveling and reduces wear over time.

16. Direct Thrust

Designates those downward forces exerted on a caster by the load, and counteracted by the top load bearing.

17. Component Thrust

Component thrust refers to the side forces exerted on the various components of the caster during use, and counteracted by the bottom load bearing.

18. Spanner Bushing / Bushing

The spanner bushing is a non-rotating sleeve that strengthens the caster’s structure, providing smoother rotation and better load distribution.

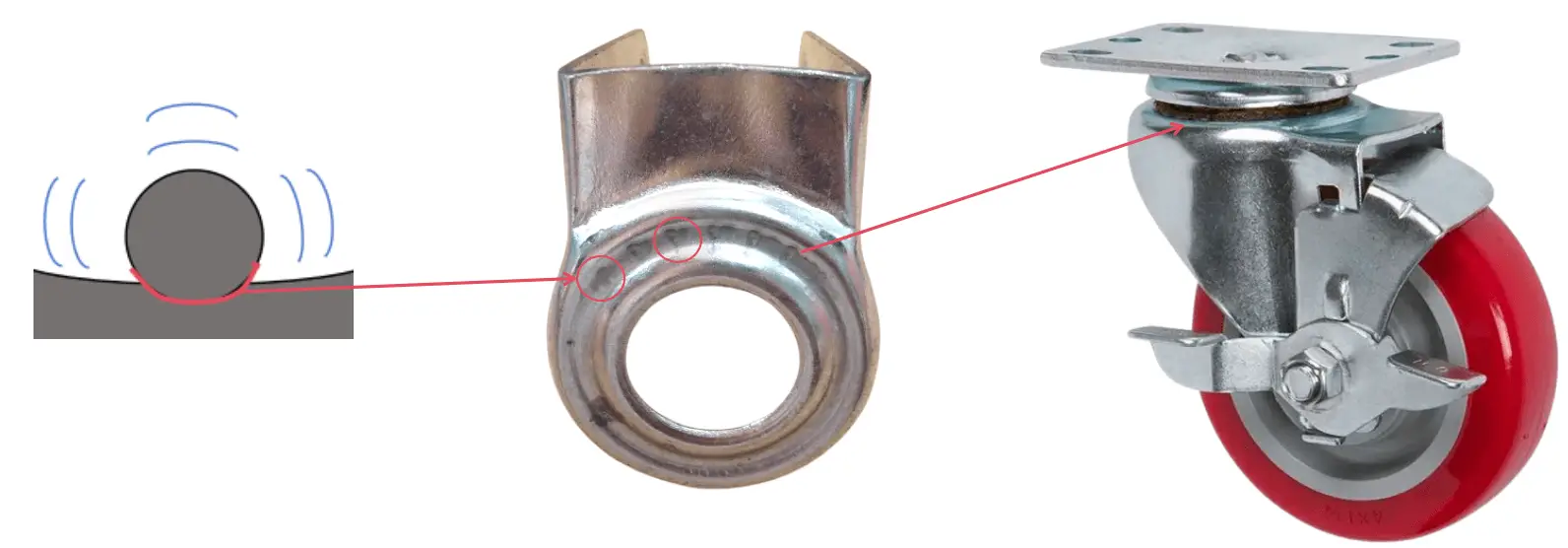

19. Brinelling

Brinelling occurs when the raceway becomes permanently deformed due to excessive loads. This deformation can affect the performance of the caster, leading to rough swiveling and impaired movement.

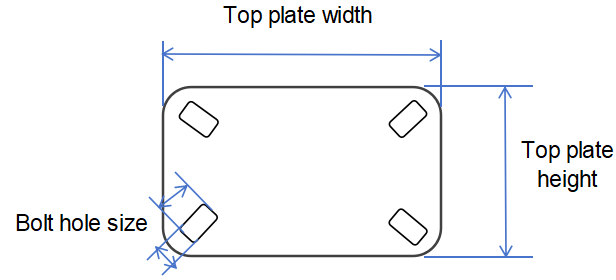

20. Mounting Plate / Top Plate Size

Mounting Plate / Top Plate Size: It is the measurement between the horizontal and vertical edges of the mounting plate.

21. Bolt Hole Pattern

The bolt hole pattern refers to the arrangement and spacing of bolt holes on a caster’s top plate. It’s essential for proper mounting to ensure a secure fit when attaching the caster to equipment.

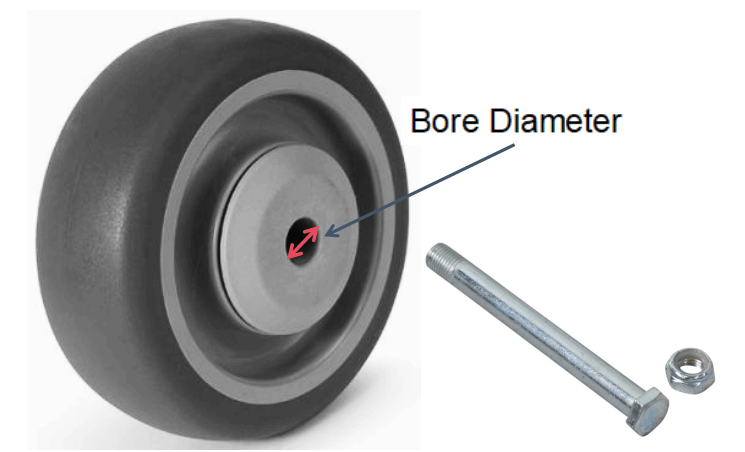

22. Bore Diameter

The bore diameter is the internal diameter of the wheel bore, determining the size of the axle that can be inserted. This measurement is crucial for ensuring proper fit and smooth wheel rotation.

23. Durometer

Durometer measures the hardness of the wheel material, affecting how the caster handles surfaces. A higher durometer rating means a harder wheel, suitable for smooth surfaces, while softer wheels are better for rougher floors.

To discover more, explore this artical for a detailed explanation of the Shore A and Shore D scales, commonly used to measure the hardness of wheel materials.

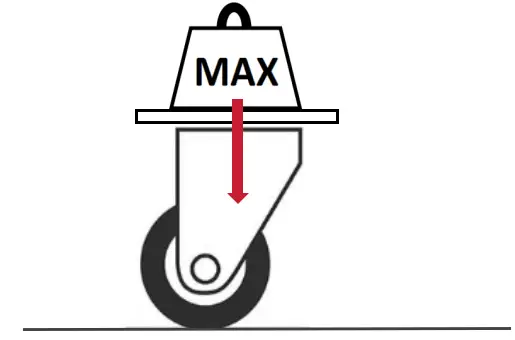

24. Dynamic Load and Static Load

What’s the difference between dynamic and static load? The dynamic load refers to the weight a caster supports while in motion. This differs from the static load, which is the weight the caster can bear when stationary.

25. Load Capacity

The load capacity is the maximum weight each caster can safely support. It’s important to select casters with a load capacity suitable for the intended use to prevent damage or failure.

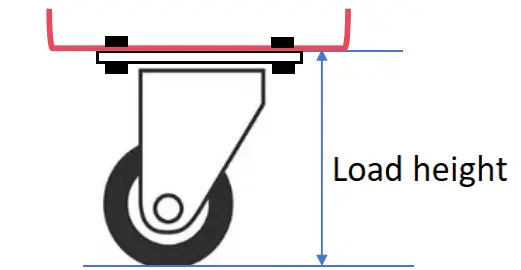

26. Load Height

Load height is the vertical distance from the floor to the bottom of the equipment mounted on the caster. This dimension affects the stability and clearance of the equipment.

27. Swivel Radius

What is Swivel Radius of a caster wheel? The swivel radius is the horizontal distance from the center of kingpin to the edge of the wheel. A larger swivel radius provides smoother turns but requires more space to maneuver.

You can also check out this video for a clearer understanding of swivel radius.

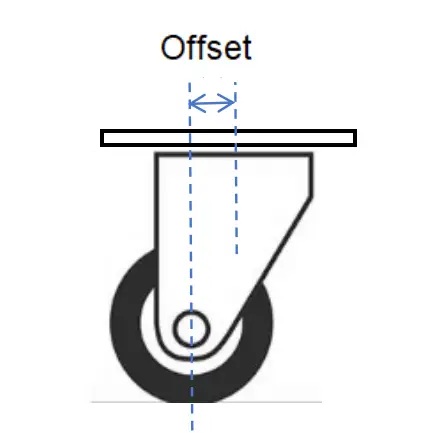

28. Offset / Swivel lead

What does Offset mean? Offset refers to the distance between the vertical centerline of the caster’s raceway and the center of the axle hole on its leg. This measurement is key in determining the caster’s maneuverability and performance.

You can also check out the below video for a clearer understanding of offset.

29. Swivel interfrence

Why swivel interference important? Caster interference refers to the necessary space around a caster wheel that allows it to swivel freely around its axis. This area, often called the swivel radius, must be clear of any obstacles. If objects intrude into this space, they can impede the caster’s movement, causing it to swivel less smoothly or potentially getting stuck. Ensuring adequate caster interference is crucial for maintaining mobility and efficiency in various applications, from furniture to industrial equipment.

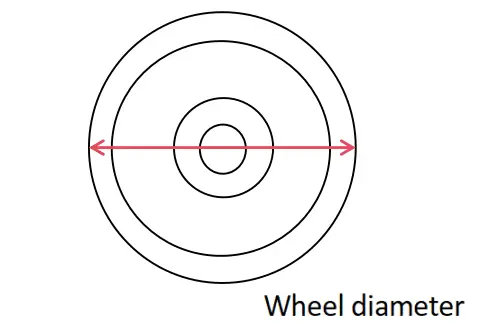

30. Wheel Diameter

The wheel diameter is the size of the wheel from edge to edge. Larger wheels provide easier movement over rough surfaces, while smaller wheels are ideal for smooth, flat surfaces.

Conclusion: Mastering Caster Terminology

Understanding these caster terminology essentials ensures you can confidently select the right caster for any application. Whether you prioritize smooth movement, load capacity, or durability, this knowledge empowers you to make informed choices tailored to your needs.

If you need further assistance or expert advice on choosing the perfect caster, contact or email us at eric@wheelswaycaster.com today—our team is ready to help you find the best solution for your project.

FAQs

-

1. What factors should I consider when selecting a caster?

You should consider:u003cbru003eu003cstrongu003eLoad capacity:u003c/strongu003e Ensure the caster can handle the weight of your equipment, including dynamic and static loads.u003cbru003eu003cstrongu003eFlooring type:u003c/strongu003e Choose a wheel material that matches your floor (e.g., polyurethane for smooth floors or rubber for uneven surfaces).u003cbru003eu003cstrongu003eEnvironment:u003c/strongu003e For harsh conditions, select casters with corrosion-resistant materials like stainless steel.

-

2. How does wheel diameter affect caster performance?

Larger wheels:u003cbru003eProvide smoother movement over uneven surfaces.u003cbru003eReduce effort needed to push or pull equipment.u003cbru003eSmaller wheels:u003cbru003eOffer better precision on flat, smooth floors.u003cbru003eAre ideal for low-clearance equipment.

-

3. Why is a total lock mechanism important?

The u003cstrongu003etotal locku003c/strongu003e feature immobilizes both the wheel and swivel, offering maximum stability. This is crucial for applications where safety and precision are critical, such as in medical equipment or industrial machinery.

-

4. How often should I inspect casters for maintenance?

Routine checks every u003cstrongu003e3–6 monthsu003c/strongu003e are recommended. Look for:u003cbru003eu003cstrongu003eWear and tearu003c/strongu003e on wheels.u003cbru003eu003cstrongu003eLoosened nuts and boltsu003c/strongu003e on the mounting plate.u003cbru003eDirt buildup in bearings or tread guards.